Boost Productivity: Just How Upgrading Undercarriage Parts Can Enhance Performance

Boost Productivity: Just How Upgrading Undercarriage Parts Can Enhance Performance

Blog Article

Discover Undercarriage Components for Heavy Machinery

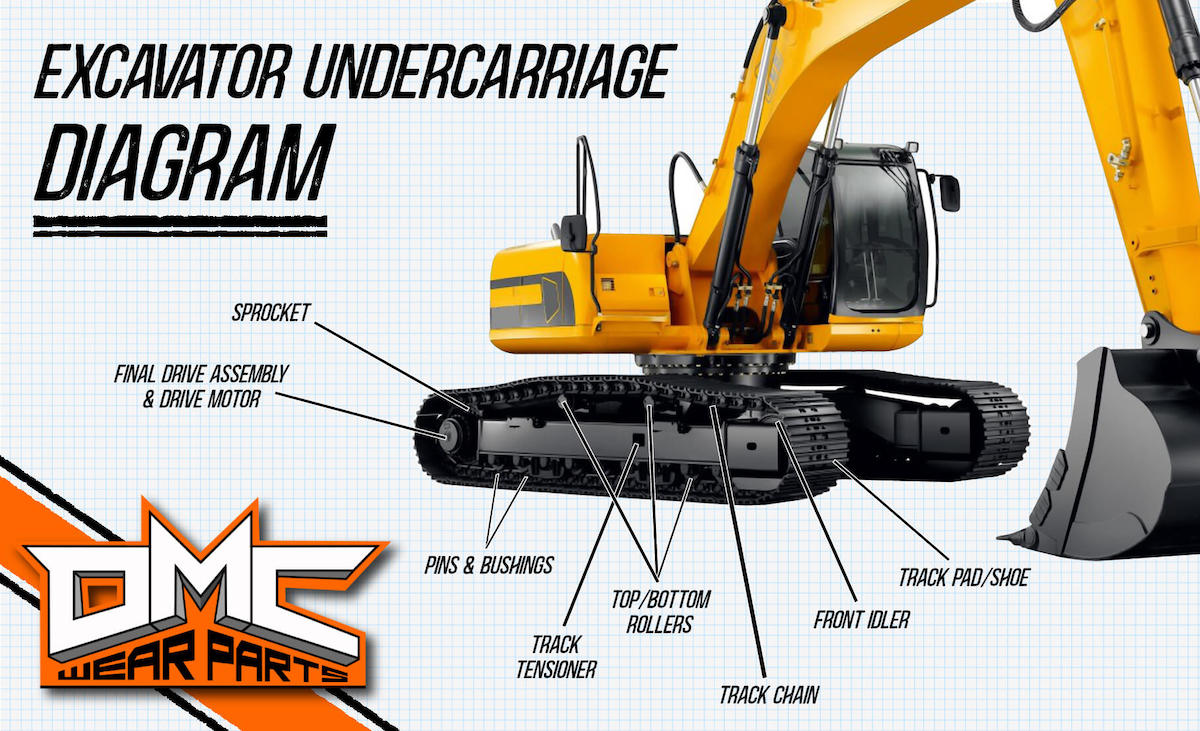

Understanding the intricacies of undercarriage components is crucial for the optimum performance and long life of heavy equipment. From track shoes to rollers, idlers, and gears, each component plays an essential role in the capability of the tools.

Relevance of Undercarriage Parts

The undercarriage components of heavy equipment play a crucial role in guaranteeing the total performance and durability of the equipment. These parts, including tracks, rollers, chains, idlers, and gears, form the structure upon which the equipment operates. A properly maintained undercarriage not just gives stability and support to the hefty machinery however additionally contributes dramatically to its functional performance and performance.

Among the key benefits of investing in high-quality undercarriage parts is the decrease of downtime and upkeep prices. By utilizing resilient components that can hold up against the roughness of durable applications, drivers can reduce the demand for constant fixings and substitutes, therefore making the most of the device's uptime and total lifespan.

In addition, properly operating undercarriage parts ensure optimal weight maneuverability, grip, and distribution, permitting the heavy equipment to operate efficiently also in tough terrains. This dependability is vital for markets such as farming, mining, and construction, where tools performance directly affects job timelines and success. Finally, the significance of undercarriage parts can not be overemphasized in preserving the efficiency and long life of hefty machinery.

Types of Track Shoes

When taking into consideration the various sorts of track footwear for hefty machinery, it is vital to review their layout and capability in relation to certain functional requirements. Track shoes are vital elements of the undercarriage system, supplying grip, stability, and weight distribution for heavy equipment such as excavators, bulldozers, and crawler cranes.

One of the most usual kinds of track shoes consist of:

** Grouser Shoes **: Featuring increased steel bars (grousers) along the shoe's surface, these track shoes provide improved grip in challenging terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser footwear but with an extra collection of grousers, these track shoes offer even higher traction and security, making them optimal for exceptionally harsh terrains.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track shoes provide maximum traction and stability, making them suitable for the most demanding problems.

Picking the best sort of track footwear is essential for optimizing the efficiency and long life of hefty equipment while making sure safety and efficiency during operations.

Feature of Rollers and Idlers

Rollers and idlers play indispensable functions in supporting and assisting the track footwear of heavy machinery throughout procedure. Rollers are round components that support the weight of the tools and make sure smooth movement along the see here surface. They help disperse the device's weight evenly, reducing endure the track footwear and reducing resonances. Idlers, on the various other hand, overview the track chain and aid preserve correct stress. By stopping too much slack or tightness in the tracks, idlers blog add to the overall security and performance of the machinery (undercarriage parts).

Additionally, rollers and idlers collaborate to keep the track footwear in positioning, avoiding them from thwarting or sliding off during procedure. Effectively operating idlers and rollers are vital for making certain the durability of the undercarriage system and making the most of the machine's performance. Regular maintenance and evaluation of these elements are necessary to identify any signs of wear or damage at an early stage, protecting against pricey fixings and downtime in the lengthy run.

Role of Gears in Equipment

Upkeep Tips for Undercarriage Elements

Effective maintenance of undercarriage elements is vital for making sure the long life and optimal performance of hefty equipment. Routine assessment of undercarriage parts such as track chains, rollers, idlers, gears, and track shoes is crucial to avoid unforeseen break downs and expensive fixings. One key maintenance idea is to keep the undercarriage tidy from debris, mud, and other pollutants that can increase wear and corrosion. It is likewise crucial to make sure proper track tension to prevent premature endure elements. Greasing the undercarriage components at suggested intervals aids to minimize rubbing and extend the life expectancy of the elements. Keeping track of for any kind of uncommon sounds, resonances, or adjustments in device performance can indicate prospective issues with the undercarriage that require immediate focus. By following these maintenance suggestions diligently, hefty equipment drivers can minimize downtime, decrease browse this site running prices, and make best use of the productivity of their tools.

Verdict

To conclude, the undercarriage components of hefty machinery play a crucial role in making certain the smooth performance and longevity of the tools. Comprehending the importance of track shoes, rollers, sprockets, and idlers, in addition to executing appropriate upkeep techniques, can greatly influence the general performance and performance of the equipment (undercarriage parts). Regular inspection and prompt replacement of worn-out parts are necessary in taking full advantage of the life-span and efficiency of heavy equipment

Rollers and idlers play integral functions in supporting and assisting the track shoes of heavy equipment during procedure.In heavy machinery, gears serve a crucial function in moving power from the engine to the tracks, making it possible for the devices to move effectively and effectively. These components are connected to the axles or final drives of the equipment and job in combination with the tracks to push the equipment ahead or backwards. Normal evaluation of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is essential to avoid unexpected failures and pricey fixings. Comprehending the relevance of track footwear, sprockets, idlers, and rollers, as well as executing appropriate upkeep techniques, can significantly affect the general performance and effectiveness of the machinery.

Report this page